Motown's Quality Control: Standardizing Excellence in the Creative Space

Part 2 of "The Blueprint of Excellence: Lessons in Scaling" , A Black History Month Series

Berry Gordy didn't wake up one day and decide to change music forever. He worked at the Lincoln-Mercury automobile plant in Detroit, watching cars move down the assembly line, and had a realization: If Ford could standardize the production of vehicles, why couldn't he standardize the production of hits?

Most people think creativity and systems are enemies. That "the magic" dies when you introduce process. That quality control belongs in factories, not creative spaces.

Berry Gordy proved them all wrong.

He built Motown, not just as a record label, but as a hit factory where excellence wasn't an accident. It was engineered, tested, and refined through one of the most sophisticated business process improvement consulting operations in history. And he did it before "operations management consulting" was even a phrase.

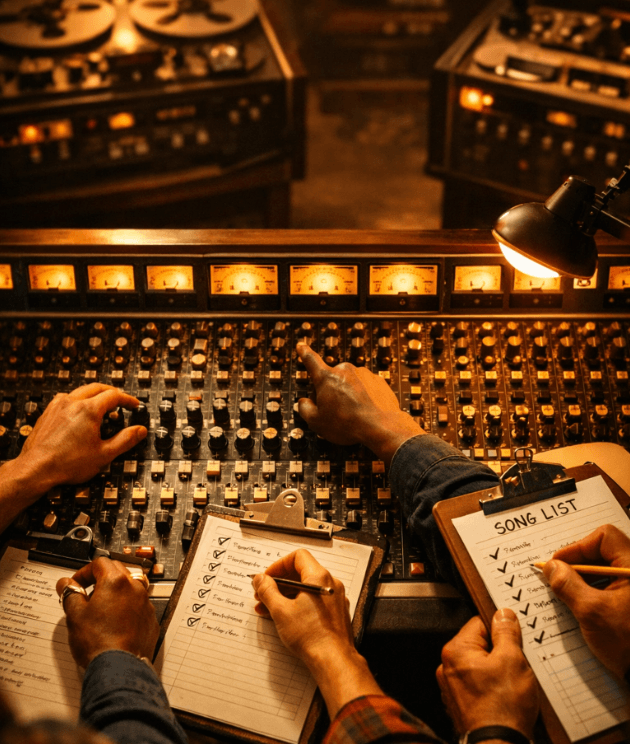

The Motown System: Where Assembly Lines Meet Art

Here's what most people miss about Motown: it wasn't Berry Gordy's genius that created the hits. It was the system he built around the talent.

Every Monday, writing and production teams would generate five new songs. They'd present their two strongest to develop into full recordings. But here's where it gets interesting, and where most modern businesses fail to replicate this level of operational excellence.

Each song didn't just get recorded once and shipped. Teams would create an average of 15 mixes per song. Some tracks got over 100 iterations. Why? Because the cost of getting it wrong internally was pennies compared to the cost of releasing a flop.

Then came the Quality Control Department.

Every Friday morning, the department would meet to evaluate the week's recordings. This wasn't just a few executives rubber-stamping approvals. This was a democratic voting process where everyone from producers to distribution staff had equal say.

No song could be released without unanimous approval.

Read that again. Unanimous.

One "no" vote, and the track went back to the drawing board, or into the vault.

Why Democratic Quality Control Actually Works

Berry Gordy did something most founders are terrified to do: he made logic the boss, not ego.

He filled his quality control meetings with people across the entire production-to-distribution cycle. A non-creative person's vote held the same weight as a legendary producer's vote. This eliminated the ownership bias that kills objectivity in most businesses.

Think about your client delivery process right now. How many decisions are made based on "well, I think it's good enough" versus "does this meet our documented standard?"

If you're like most service-based businesses, you probably don't even have a documented standard.

Motown's approach involved three mechanisms that every business scaling past $500K needs to understand:

1. Removing Ego and Bias

Gordy stated it plainly: "I took the democratic approach because although I was in charge at Motown, I made logic the boss: no egos or politics allowed."

He hired people he considered better songwriters and producers than himself, then gave them authority within structure. The result? A learning-oriented culture where standardized excellence emerged through systematic critique rather than individual genius.

2. Strategic Gatekeeping

Motown prioritized having "more flops within the company and fewer on the streets." They discarded over 20 songs and 10 recordings weekly, expensive internal failures, yes, but far preferable to costly market failures.

This is workflow optimization at its finest: catching problems early when the cost to fix them is low, rather than after they've reached the client.

3. Immediate Feedback Loops

The quality control verdicts weren't just rejections. They were training opportunities. Songwriters and producers learned what worked, what didn't, and why. Gordy's rule was simple: "If you don't get them in the first 4-8 bars, you gotta go back to the drawing board."

Clear standards. Clear feedback. Clear improvement.

The Fear That Kills Growth: "Systems Will Kill Our Vibe"

Let's address the elephant in the room.

Most founders resist standardization because they believe it will strip away what makes their business special. They've built their reputation on being "different," on the personal touch, on the boutique experience.

And they're right to protect that. But they're wrong about systems being the enemy.

Motown didn't produce robotic, cookie-cutter music. They produced Stevie Wonder, Marvin Gaye, Diana Ross, The Temptations, The Supremes, The Jackson 5, artists who were wildly different from each other, yet all carried the Motown standard of excellence.

The system didn't kill the creativity. It **freed the talent to focus on what they did best** while the operational infrastructure handled quality control, artist development, and market readiness.

Here's the hard truth: If your client experience depends entirely on who is handling the account that day, you don't have a brand. You don't have a system. You have a collection of individuals hoping nothing breaks.

And when you're trying to scale? That hope is expensive.

What This Looks Like in Modern Business

You're not running a record label, but the operational principles are identical.

Every client project you deliver goes through stages: discovery, strategy, execution, revision, delivery. The question is whether those stages are standardized and repeatable or dependent on whoever happens to be working that day.

Consider these scenarios:

Scenario A: No Standardization

- Client onboarding varies by account manager

- Quality depends on who's having a good week

- Training new team members takes months

- You can't confidently predict project timelines

- Some clients get white-glove service; others fall through cracks

Scenario B: Motown-Level Standardization

- Every client moves through the same proven process

- Quality checkpoints catch issues before delivery

- New hires get up to speed in weeks, not months

- You can forecast capacity and revenue accurately

- Every client gets the same high-touch experience

Which scenario builds enterprise value? Which one lets you sleep at night?

This is why business systems consultant work isn't just about "being organized." It's about turning lucky breaks into repeatable results. It's about [building operations that don't depend on you being the bottleneck].

The Friday Morning Question You Should Be Asking

Berry Gordy's Friday quality control meetings asked one question: Is this good enough to represent Motown in the marketplace?

What's your version of that question?

- Is this client deliverable up to our standard, or just "good enough for now"?

- Would we be proud if this project ended up in a case study?

- If a prospect asked for references from this client, would we be confident in the response?

If you can't answer "yes" consistently, you don't have a quality control problem. You have an operations management consulting problem.

Your team isn't failing you. Your lack of documented standards, clear feedback loops, and systematic checkpoints is failing them.

Building Your Own Quality Control System

You don't need 15 mixes per deliverable. But you do need:

Documented Standards: What does "done" look like? What's the minimum acceptable quality? Who approves what?

Regular Review Cycles: Weekly check-ins where work is evaluated against standards: not subjective opinions.

Democratic Feedback: Get input from multiple perspectives. Your best account manager might spot something your operations lead misses.

Early Detection: [Catch revenue leaks and delivery gaps](https://apexmogulsgroup.com/blog/the-10-minute-backend-leak-test--is-your-business-bleeding-money) before they reach the client.

Clear Escalation Paths: When something doesn't meet standard, what happens? Who fixes it? What's the timeline?

This is the difference between a business that grows through heroic individual effort and one that scales through workflow optimization and repeatable systems.

The Motown Standard for Modern Business

Berry Gordy proved something that most consultants charge six figures to teach: Systems don't kill excellence. They multiply it.

The artists at Motown became legends not despite the structure, but because of it. The quality control meetings, the artist development programs, the standardized processes: these didn't restrict creativity. They created the conditions for creativity to thrive at scale.

Your business is no different.

Whether you're delivering marketing services, financial consulting, design work, or coaching programs, the principle holds: If you can't systematize your excellence, you can't scale it.

And if you can't scale it, you're building a job, not a business.

---

Ready to find out where your backend is bleeding opportunities? Our [Apex Business Backend Audit]($97) identifies the exact gaps in your delivery systems, client handoffs, and quality control processes: so you can stop hoping things work and start knowing they do. Get your personalized audit within 48 hours and see exactly where to tighten up your operations.